M. Fatkur Rohman

Supply Chain Enthusiast

Hi there! 👋

Supply Chain Enthusiast

Fresh graduate in Industrial Engineering focused on logistics, inventory control, and supply chain strategy. Eager to contribute to impactful SCM roles using practical internship experience and analytical thinking.

M. Fatkur Rohman

Supply Chain Enthusiast

Industrial Engineering graduate with interest and specialization in Supply Chain Management, with hands-on internship experience in the energy and mining industry. Have internship experience as Inventory Control & Warehouse staff at PT PLN Nusantaran Power and Procurement & Supply Chain Management at PT Bukit Makmur Mandiri Utama site Indonesia Pratama.

With a strong foundation in Industrial Engineering, I build supply chain competencies through real projects such as demand forecasting, inventory control in warehouses, and logistics monitoring system design. I believe that supply chain efficiency starts with a good understanding of data. My goal is to become a supply chain specialist who is able to bridge data analysis and company strategic decisions.

Education

Industrial Engineering

Sebelas Maret University

GPA : 3.57/4.00

Relevant Coursework : Cost Analysis and Estimation, Probability Theory, Statistics, Operation Research, Supply Chain Engineering, Production Planning and Control, Project Management, and Sustainability Supply Chain Management.

Science

SMAN 1 Kraksaan

GPA : 89.93/100

Experience

Business Owner

Sobat Rasa / Surakarta, Central Java

(Jan – May 2025)

Lead a business with a turnover > of Rp.15,000,000 per month and successfully market and sell > 7 types of products offline or online to hundreds of customers.

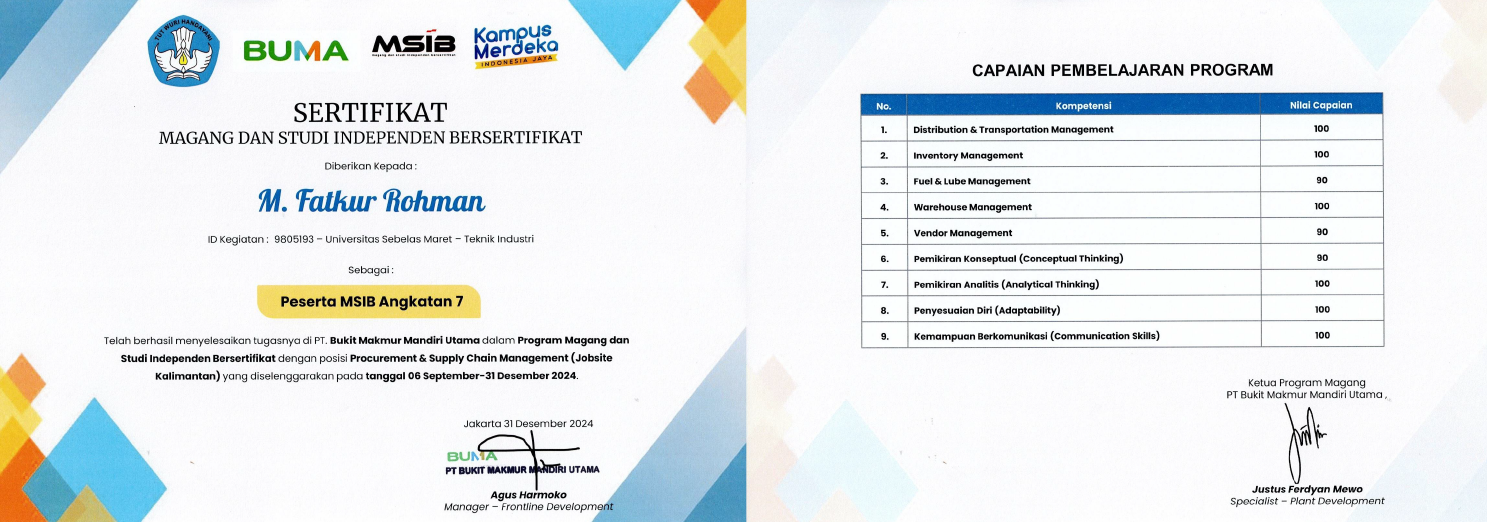

Procurement & Supply Chain Management

PT Bukit Makmur Mandiri Utama (BUMA) / Kutai Kartanegara, East Kalimantan

(Sep – Dec 2024)

In the fourth quarter of 2024, I conducted demand forecasting for each spare part item in the warehouse. Through this approach, I managed to optimize the inventory of critical items and reduce the inventory value by 23.37% or equivalent to Rp1,238,321,347 per month. In addition, I also initiated a storage time monitoring system that proved effective in reducing storage costs by Rp6,550,000 per month and saving 3.5 hours of work time each month.

Marketing Analyst

Sharing Thing / Surakarta, Central Java

(Jun – Jul 2024)

Compiled market reports and competitor analysis and helped design a data-driven marketing strategy that increased campaign effectiveness by 25%. Working closely with cross-functional teams, I ensured the strategy was aligned with business objectives. The use of analytics tools also reduced operational costs by 20%.

Inventory Control & Warehouse

PT PLN Nusantara Power / Probolinggo, East Java

(Jan – Apr 2024)

During my internship at PT PLN Nusantara Power (PLTU Paiton) January-April 2024 in Probolinggo, I managed 24,000 items using the EOQ method. I also handled coal inventory through consumption forecasting, setting safety stock with service levels of 90% and 95%, supervising the loading and unloading process, mechanical sampling control, and administration with suppliers and PLN NP Center.

Top Skills

SAP S/4HANA

MS EXCEL

MS WORD

POWERPOINT

ACCURATE

ARENA

Certificate

MSIB Batch 7 PT BUMA

MSIB Batch 7 PT BUMA

PKL PT PLN Nusantara Power

PKL PT PLN Nusantara Power

Inventory Management Awareness

Inventory Management Awareness

Warehouse Management Awareness

Warehouse Management Awareness

Microsoft Office Course by Udemy

Microsoft Office Course by Udemy

Google Sheets Course by Udemy

Google Sheets Course by Udemy

Procession Class

Procession Class

Staff HRD

Staff HRD

Gerakan Mengajar Desa Jawa Tengah

Gerakan Mengajar Desa Jawa Tengah

Head of Logistic DEMA

Head of Logistic DEMA

Logistic Staff

Logistic Staff

Projects

Here are the projects that I have undertaken during my education in college and internships.

Safe Summit Guardian

Safe Summit Guardian

Lecture

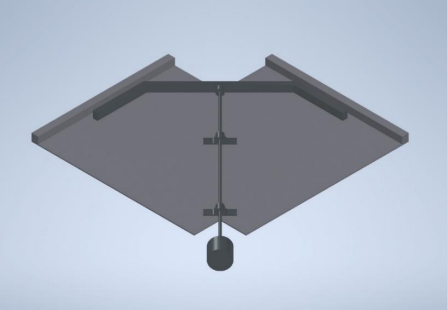

Design of Jig Assistive Devices in the Welding Process at Mas Rachmad Workshop

Design of Jig Assistive Devices in the Welding Process at Mas Rachmad Workshop

Lecture

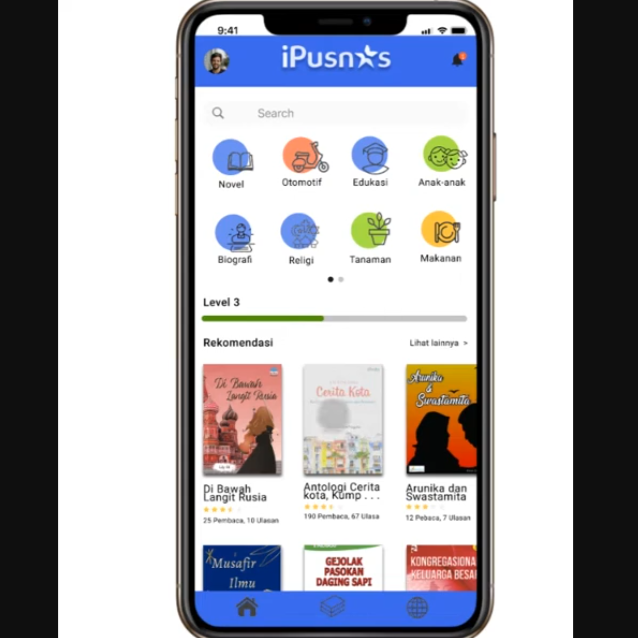

Redesign iPusnas

Redesign iPusnas

Free Project

Critical Goods Inventory Control at PT Bukit Makmur Mandiri Utama Site Indonesia Pratama Using ABC Analysis and Monte Carlo Simulation

Critical Goods Inventory Control at PT Bukit Makmur Mandiri Utama Site Indonesia Pratama Using ABC Analysis and Monte Carlo Simulation

Internship

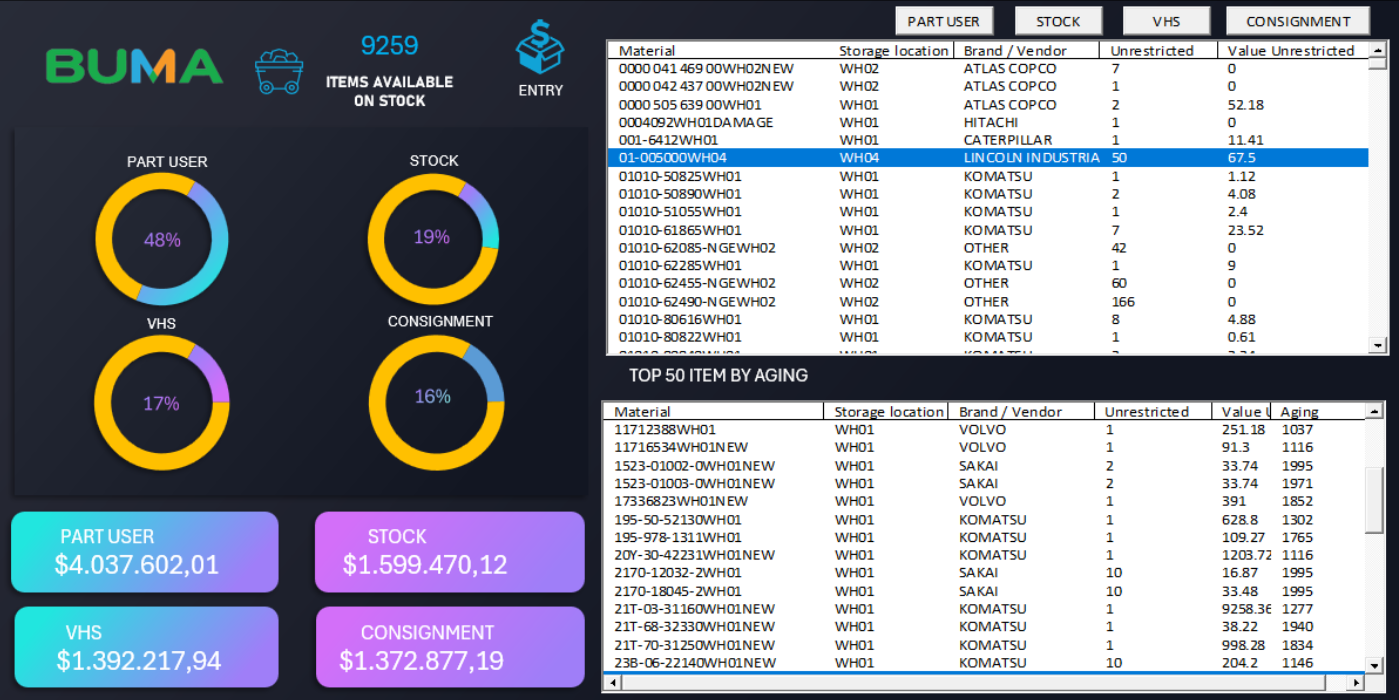

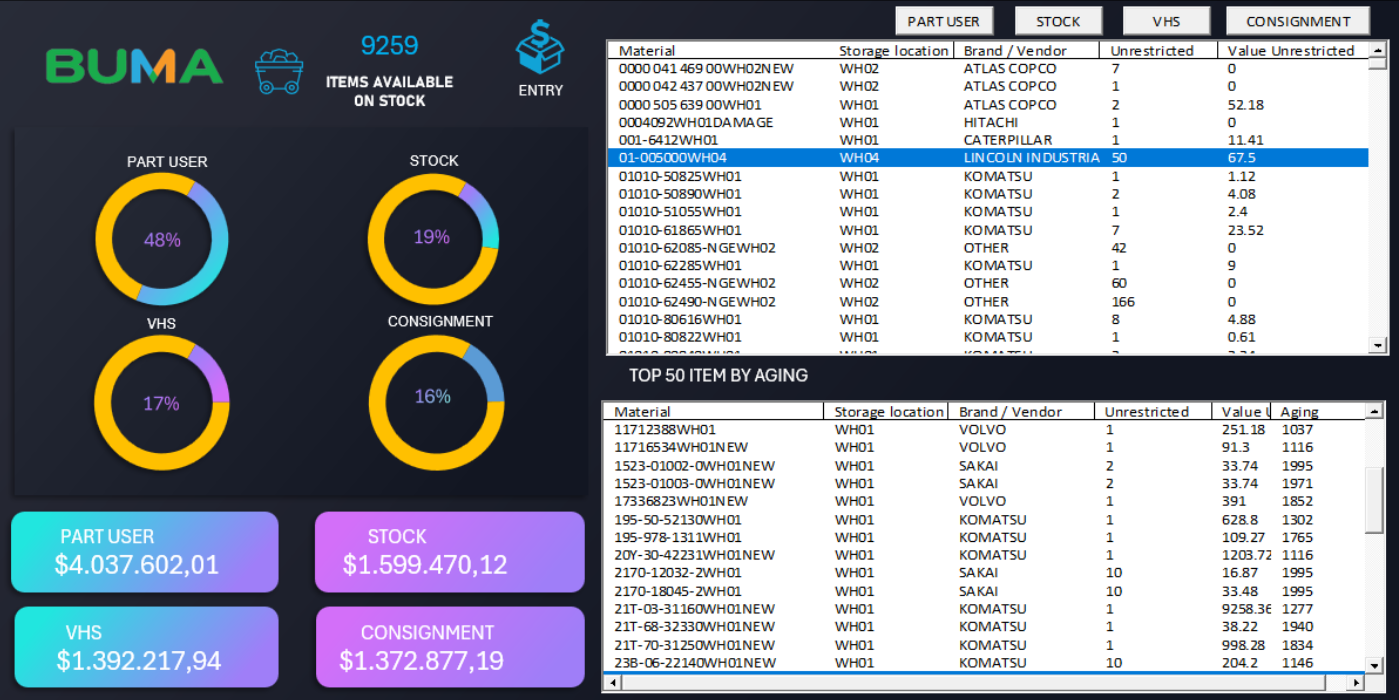

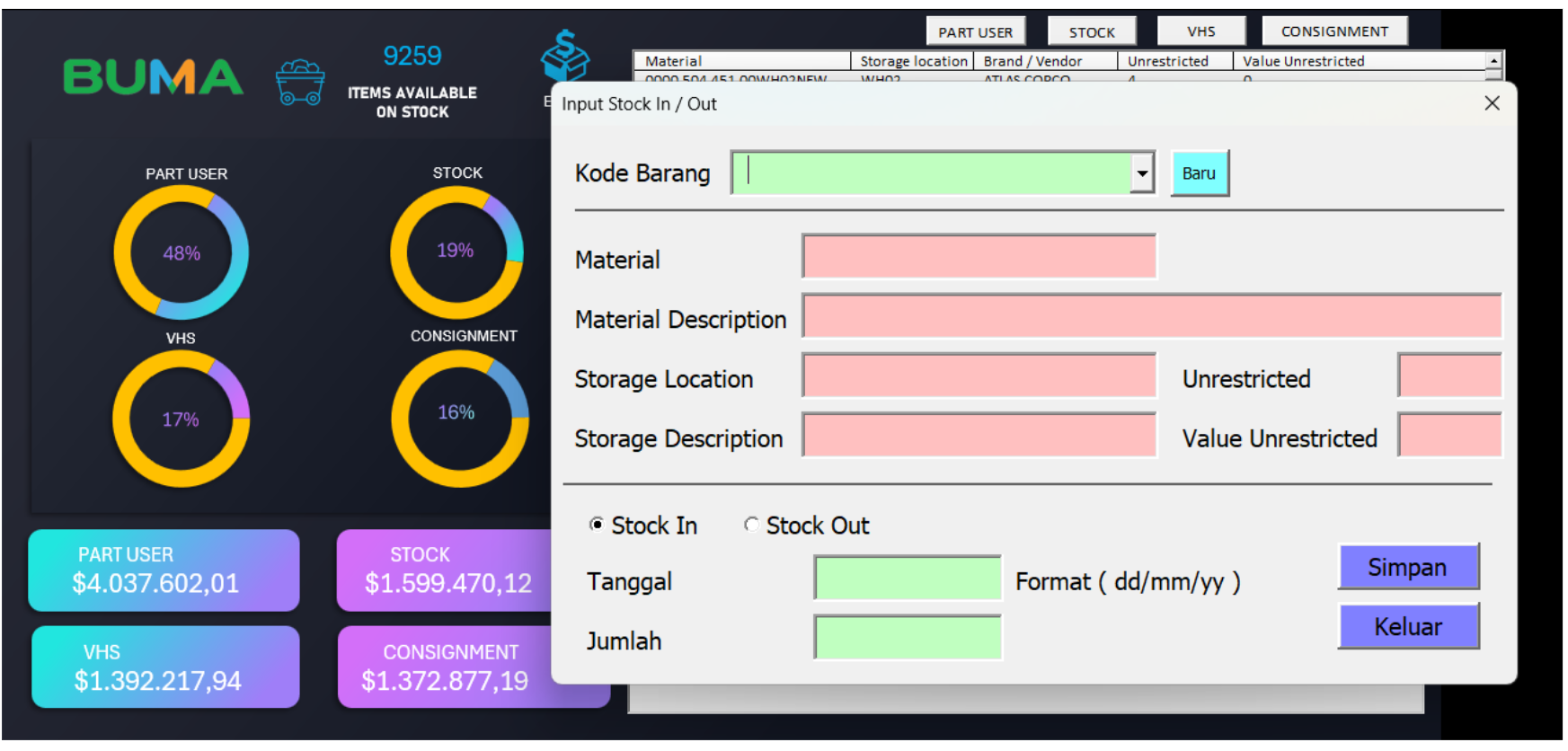

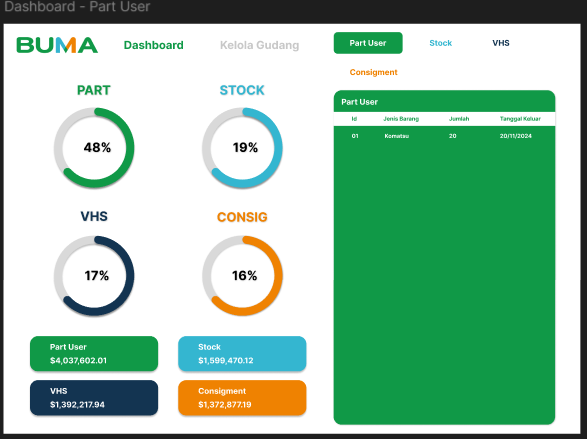

Dashboard Design for Monitoring the Storage Time of Goods in the Warehouse of PT Bukit Makmur Mandiri Utama Site Indonesia Pratama

Dashboard Design for Monitoring the Storage Time of Goods in the Warehouse of PT Bukit Makmur Mandiri Utama Site Indonesia Pratama

Internship

Optimization of Inventory Management to Minimize Losses in Coal Storage at PT PLN Nusantara Power Paiton 9 Generating Unit

Optimization of Inventory Management to Minimize Losses in Coal Storage at PT PLN Nusantara Power Paiton 9 Generating Unit

Internship

Implementation of Sustainable Supply Chain Management in the Forestry Industry

Implementation of Sustainable Supply Chain Management in the Forestry Industry

Internship

Safe Summit Guardian

Safe Summit Guardian

Lecture

Design of Jig Assistive Devices in the Welding Process at Mas Rachmad Workshop

Design of Jig Assistive Devices in the Welding Process at Mas Rachmad Workshop

Lecture

Critical Goods Inventory Control at PT Bukit Makmur Mandiri Utama Site Indonesia Pratama Using ABC Analysis and Monte Carlo Simulation

Critical Goods Inventory Control at PT Bukit Makmur Mandiri Utama Site Indonesia Pratama Using ABC Analysis and Monte Carlo Simulation

Internship

Dashboard Design for Monitoring the Storage Time of Goods in the Warehouse of PT Bukit Makmur Mandiri Utama Site Indonesia Pratama

Dashboard Design for Monitoring the Storage Time of Goods in the Warehouse of PT Bukit Makmur Mandiri Utama Site Indonesia Pratama

Internship

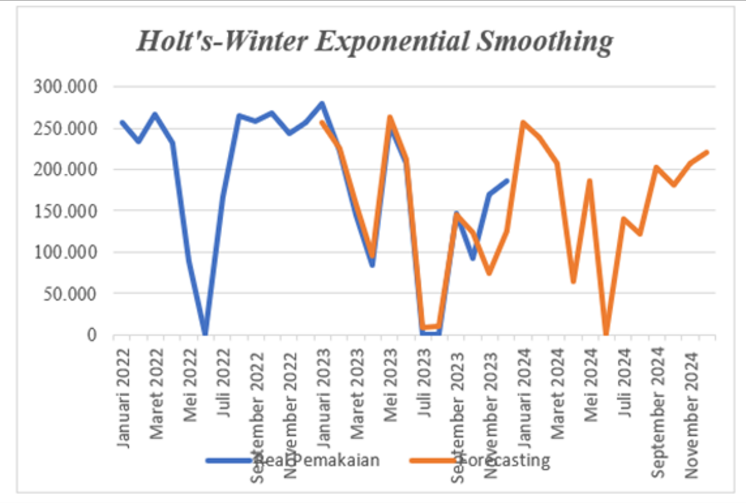

Optimization of Inventory Management to Minimize Losses in Coal Storage at PT PLN Nusantara Power Paiton 9 Generating Unit

Optimization of Inventory Management to Minimize Losses in Coal Storage at PT PLN Nusantara Power Paiton 9 Generating Unit

Internship

Implementation of Sustainable Supply Chain Management in the Forestry Industry

Implementation of Sustainable Supply Chain Management in the Forestry Industry

Internship

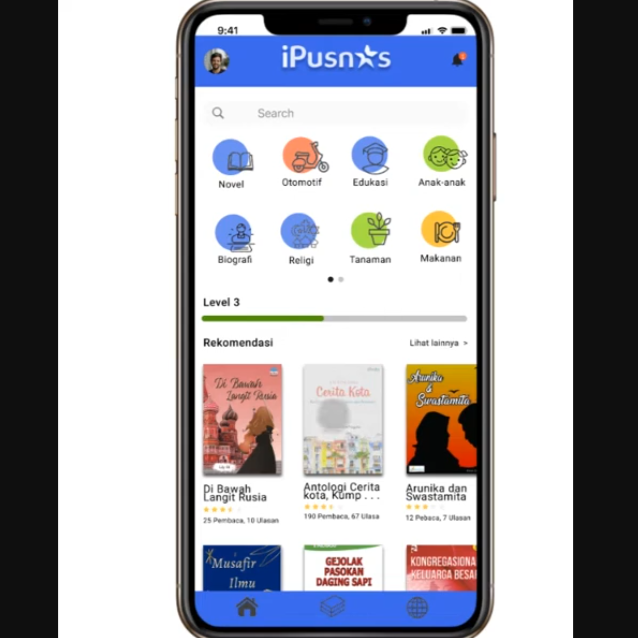

Redesign iPusnas

Redesign iPusnas

Free Project

Safe Summit Guardian

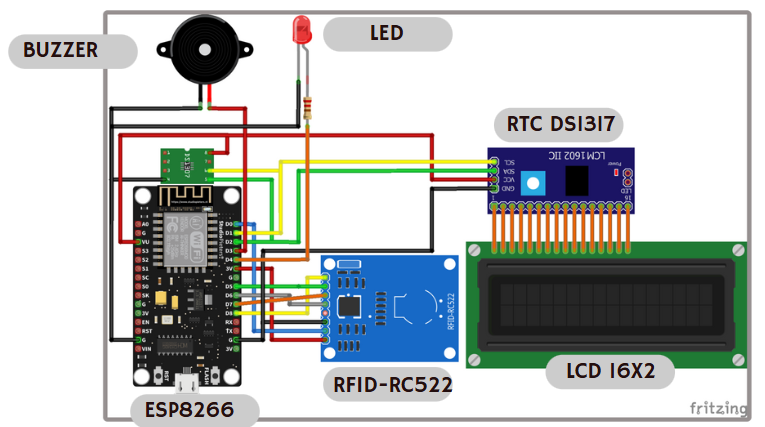

Safe Summit Guardian is an Internet of Things (IoT) based mountain climber safety monitoring system. This project aims to improve safety during climbing activities by utilizing RFID technology and the NodeMCU ESP8266 microcontroller integrated with the Telegram application. The system works by recording the presence of hikers through RFID cards scanned at each hiking post, then sending identity data and time in real-time to Telegram. In addition, this tool is also equipped with an SOS feature, where climbers can trigger an emergency signal by scanning five times in a row. In this project, I played a role in the testing and repair stage of the device, ensuring that all components, such as the RFID sensor, RTC, LCD, buzzer, and LED. Work optimally and can provide a fast and accurate response. This project resulted in a prototype that is not only functional, but also resistant to use in an outdoor environment, so it is expected to be an innovative solution to improve safety in mountaineering activities.

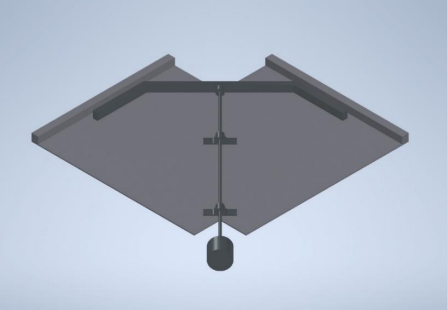

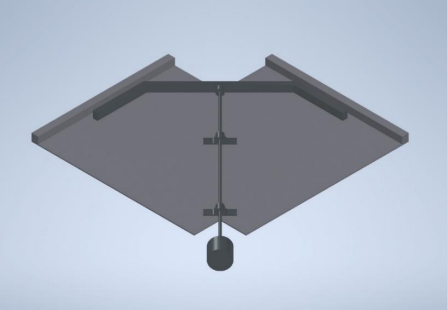

Design of Jig Assistive Devices in the Welding Process at Mas Rachmad Workshop

This project is a design of jig tools for the welding process at Mas Rachmad Workshop, an MSME engaged in the repair and manufacture of metal-based tools. The main problem identified is the high level of human error in the welding process, such as measurement errors, placement of materials, and machine settings, as well as low work safety aspects. To overcome these problems, a jig was designed as a production aid using the Poka Yoke method approach to prevent errors from the beginning of the process. This jig allows the workpiece to be positioned and locked precisely during the welding process, thereby increasing efficiency, reducing product defects, and improving work safety standards. The final result of this project is a prototype jig that is able to improve productivity and work quality while supporting the application of occupational safety and health (K3) principles in a small industrial environment.

Redesign iPusnas

Critical Goods Inventory Control at PT Bukit Makmur Mandiri Utama Site Indonesia Pratama Using ABC Analysis and Monte Carlo Simulation

This project aims to optimize the inventory control of critical goods at PT Bukit Makmur Mandiri Utama Indonesia Pratama site during the period October 2024 to September 2025. In the face of increasing coal production targets, the company is required to maintain the availability of spare parts so that operations are not disrupted. The method used is ABC Analysis to classify items based on annual consumption value, and Monte Carlo Simulation to predict future demand based on historical distribution. The classification results show that 13 items are classified in category A (critical). For these items, safety stock values were determined, as well as minimum and maximum inventory limits using the minimum and maximum inventory level approach. Simulations were conducted to compare the costs between the research planning results and the practices applied in the field. The results show that this approach is able to generate cost efficiency of Rp. 1,238,321,348 per month, or about 23.37% lower than the actual costs in the field. Thus, the integration of ABC Analysis and Monte Carlo Simulation methods has proven effective in improving the efficiency of inventory management and supporting the smooth operation of the company.

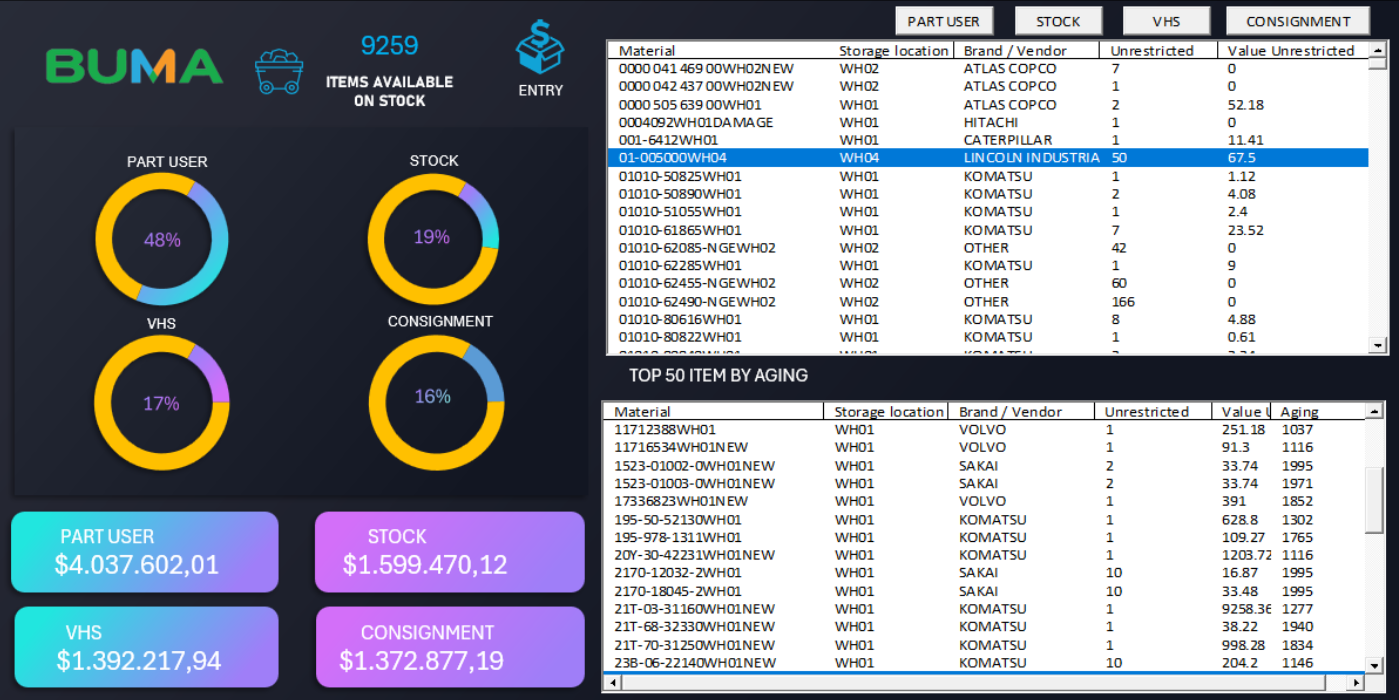

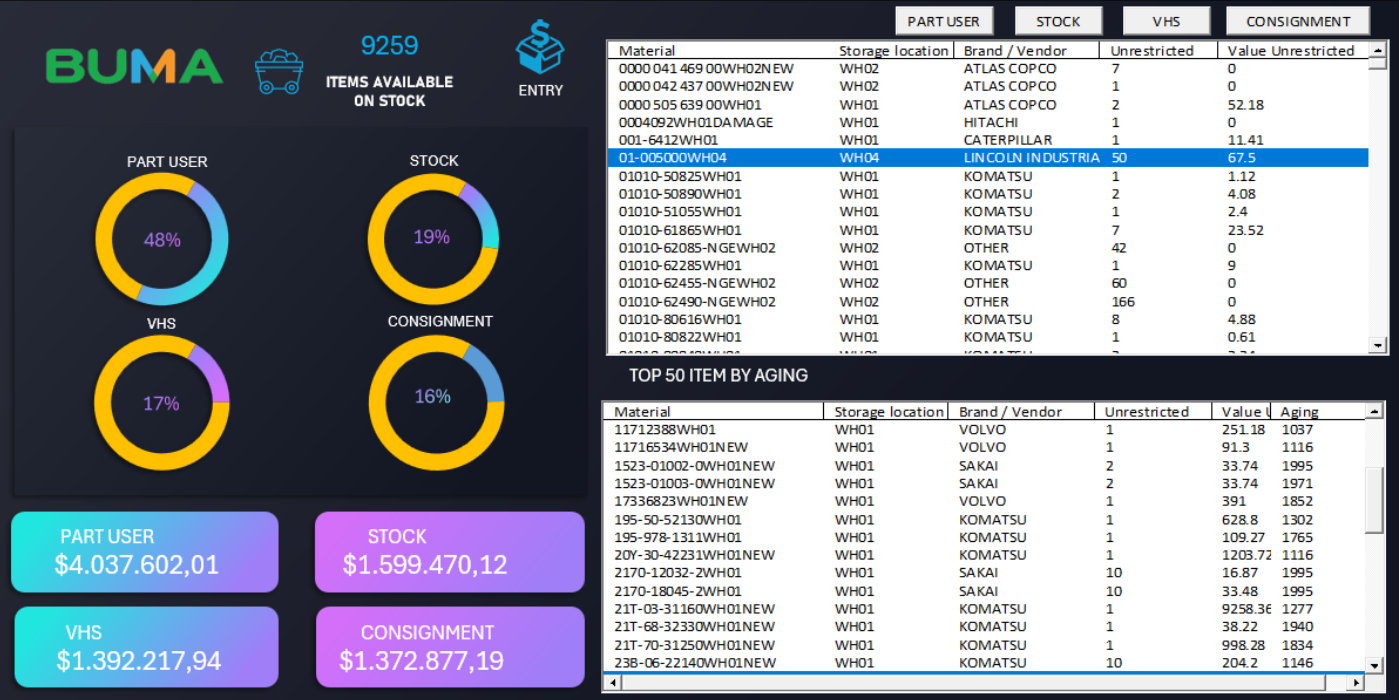

Dashboard Design for Monitoring the Storage Time of Goods in the Warehouse of PT Bukit Makmur Mandiri Utama Site Indonesia Pratama

This project is the development of a dashboard monitoring system to overcome the problem of accumulation of goods in the warehouse of PT Bukit Makmur Mandiri Utama (BUMA) Indonesia Pratama site, especially in the category of user ordered parts. The main problem faced is the limited capacity of the warehouse due to the high number of goods that are not immediately taken by the user, which causes a decrease in operational efficiency and an increased risk of overstock. Through the Failure Modes, Effects, and Criticality Analysis (FMECA) approach, it was found that the high risk in the binning process was the top priority. The solution developed is an Excel Macro VBA-based and Web-Based dashboard system that is able to record the shelf time of goods, display the aging of goods in real-time, and assist the logistics team in prioritizing the release of goods from the warehouse. The main features include recording incoming and outgoing stock, visualizing the proportion of goods categories, and listing aging part users based on value and shelf life. Simulation results show that the system is able to increase the efficiency of goods release from 29.37% to 99.60%, as well as generate potential operational cost savings of up to Rp8,050,000 per month. The dashboard supports data-driven decision-making and can be integrated with a warehouse management system (WMS) to sustainably improve efficiency and productivity.

In this project I also developed the WMS system into a form based on the website. Here is the UI display in the form of a website :

You can visit the WMS UI in the form of a website at the following link :

Optimization of Inventory Management to Minimize Losses in Coal Storage at PT PLN Nusantara Power Paiton 9 Generating Unit

This project aims to forecast the need for coal usage and determine the optimal level of safety stock and reorder point to support the smooth operation of the power plant at PT PLN Nusantara Power Paiton 9 Generation Unit. The main focus of the research is to optimize the management of coal fuel inventory, which is a vital component in the power generation process at the PLTU. The problems faced include supply fluctuations, the risk of stock shortages, and the threat of spontaneous combustion due to excessive coal accumulation. To overcome this, historical data on coal consumption for the period 2022-2023 was analyzed using the Time Series Exponential Smoothing method, namely Single, Holt, and Holt-Winter. Evaluation of model performance is done by comparing the error value (MAPE), so that the method with the best accuracy can be selected. Furthermore, safety stock calculations are carried out based on variations in demand and lead time, as well as determining reorder points so that reorders can be made on time. This project produces recommendations for a more accurate and reliable coal demand planning system, which directly contributes to the efficiency of the energy supply chain and mitigates the risk of fuel shortages in the power plant environment.

Implementation of Sustainable Supply Chain Management in the Forestry Industry

This project aims to analyze and minimize the negative impacts of Perum Perhutani’s supply chain through the approach of Sustainable Supply Chain Management (SSCM). The analysis focuses on the economic, social, and environmental aspects of procurement, production, distribution, and consumption processes. Through field observations and process mapping, opportunities were identified for cost efficiency and emission reduction. Recommendations include selecting environmentally friendly vendors, maintaining production equipment, reducing distribution travel distances, and implementing product recycling incentive schemes to create a more sustainable supply chain.

Phone

Phone

Email

Email